Model Dairy Plant

A state-of-the-art Commercial Dairy Plant was established during 1995 at NDRI, Karnal through the financial assistance and installed onturnkey basis by the National Dairy Development Board. The Plant has been designed to handle 60,000 liters (Ltrs.) of milk per day and is presently running in full capacity.

Special Features

- Model Dairy Plant provides one year In-plant training to the students of B.Tech. (DT) of the N.D.R.I. Deemed University during the 4th year of the course curriculum.

- The students are provided with complete infrastructure for training, which helps them in gaining sufficient experience in managing the modern commercial Dairy Plant and instills confidence in handling real life problems in production management.

- It also provides infrastructure facilities to the scientists of NDRI for scaling up R & D concepts from laboratory scale to industrial scale under commercial environment.

Model Dairy Plant (MDP), an autonomous unit of ICAR, is independently managed by a committee, whose Chairman is the Director of NDRI. The other committee members are: 1) Representative of NDDB; 2) A.D.G., ICAR; 3) Managing Director, Mother Dairy Fruit & Vegetable Pvt. Ltd., Delhi; 4) General Manager (MDP) as Convener. The Head, Dairy Technology Division, NDRI has been identified as Coordinator for matters related to Model Dairy Plant.

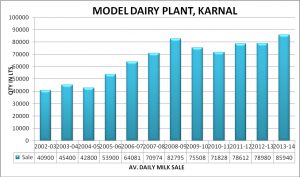

Liquid Milk Processing/Packaging (Capacity 60000 LPD)

MDP is currently engaged in processing and packaging of milk for Mother Dairy in five different variants (Full Cream, Standard, Toned, Double Toned and Skim Milk). MDP is presently processing / packing 70 – 80 TLPD of polypack Milk in all the varieties for Mother Dairy, Delhi. The plant is running in three shifts and the supplies from MDP are dispatched in the evening & morning to Delhi market thereby utilizing the plant to more than its full capacity.

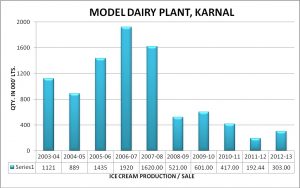

Ice-Cream Manufacture (Capacity 12000 LPD)

MDP is in agreement with Mother Dairy for processing / packing of Ice-cream in Mother Dairy brand on job work to the tune of 7000 liters per day (yearly average for 240 days operation) thereby utilizing the full capacity of the unit. The ice cream manufactured at MDP is of different varieties i.e. Vanilla, Strawberry, Shahi Malai, Kewra, Thandai, Butter Scotch etc. and as per the requirements of Mother Dairy.

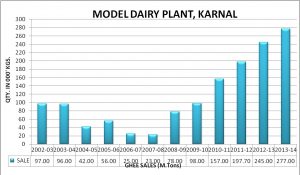

Ghee Manufacturing (Capacity 800 kg per day)

MDP manufactures Cow Ghee from Cow Butter purchased from different State Federations and its production is not taken as per demand. All the Ghee manufactured at MDP is being sold through the MDP Sale Counter.

Cheese and Paneer (Capacity 1500 Kg per Day):

MDP is also engaged in training students in manufacturing of Cottage Cheese, Processed Cheese, Paneer on trial basis. The section is operated occasionally for the purpose of taking trials and making the students familiar with the manufacturing details.

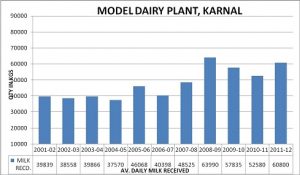

Procurement of Milk

MDP does not have its own infrastructure for milk procurement and is receiving milk on behalf of Mother Dairy from the units of Punjab / Rajasthan / Uttar Pradesh State federations on NMG rates. The average milk procurement per day is around 60,000 to 70,000 LPD, which is sufficient to meet day to day demand of different milk variants being packed at MDP.

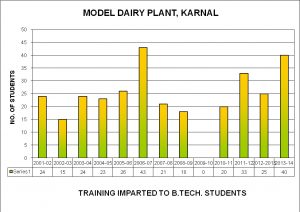

Training to the Students

As its primary objective, Model Dairy Plant is providing In-plant training to the 4th B.Tech. (DT) students of NDRI (Deemed University). The students are provided with In-plant Training Manual comprising of unit wise operation covering all the sections of the Dairy Plant. Since its inception in 1996, Model Dairy Plant has provided training to fifteen batches of B.Tech.(DT) students. The student trainees are provided Rs.1500/- per month as stipend. The total 451 no.of students trained so far. Total Rs.53.76 lacs paid as stiphend till date to the students of B.Tech(DT) of NDRI(Deemed University).

Students are given hands on experience for plant operations and are trained to manage the shift activities of the plant under the guidance of trained technical staff. In addition to the above, students are also made to involve in other activities like KAIZENs, Small Group Activities etc. The feedback regarding Inplant Training, from the student’s trained at MDP and now working in different capacities with different organizations is quite positive and encouraging.

Quality Management System

Model Dairy Plant is presently certified under the Food Safety Management System (FSMS) since January 2011 and certified under FSMS IS:22000:2005.

HRD Programmes

MDP has well trained Technical Staff to handle the various operations of the Plant for further upgrading the knowledge and skill of the employees, MDP is continuously taking up HRD programs from external agencies for up-gradation of knowledge and motivation of the employees & student trainees, which has been quite beneficial and helpful both to the employees and the organization.

KAIZENS & SGAs

MDP has started KAIZEN’s (improvements) and Small Group Activities (SGA) for its continued improvements by involving all the employees, students and the floor level staff.

Visit by Dignitaries

Model Dairy Plant is regularly visited by dignitaries from India & abroad. Faculty members and students of different institutions also visit the plant. Visitors and dignitaries, so far visited, have appreciated the quality of work vis-a-vis hygiene and the facilities made available for training the students of Deemed University NDRI.

Awards and Recognition

The continuous improvements in the system have made MDP an award winning organization. MDP was awarded the Productivity Award for Best Productivity Performance in Dairy Development & Production (2003-2004). The award was presented by Sh. Sharad Pawar, H’able Union Minister of Agriculture, Govt. of India in a glittering function held at Scope Complex, New Delhi on May 10, 2005 jointly to the Chairman MDP and General Manager MDP.

- Back to previous page

- |

-

Page last updated date:11-02-2025 02:57 PM